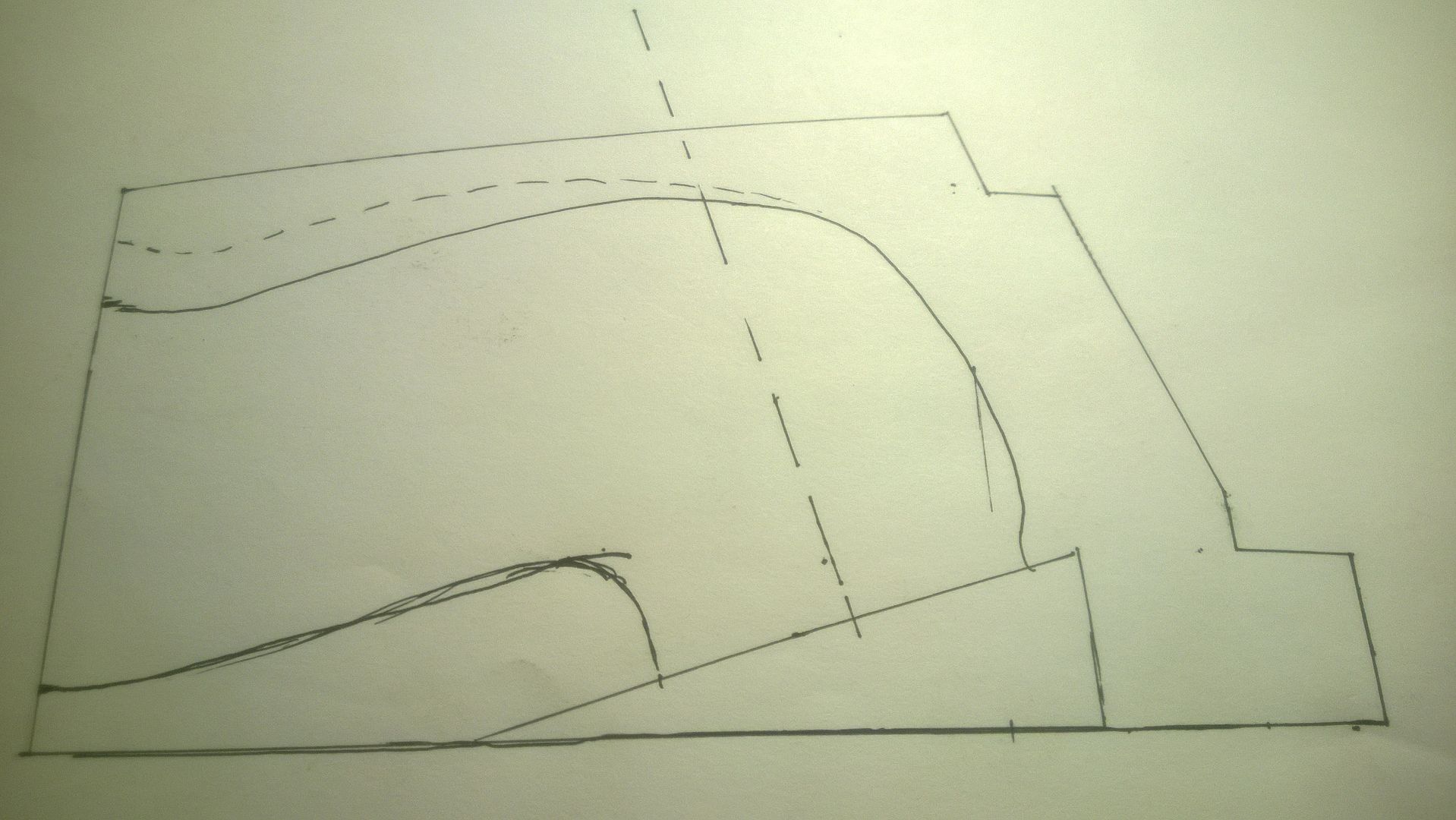

So I took my motor to the dyno and made some good numbers for a Street Build 440, but the gears didn't stop turning there. So I'll throw my thoughts out there and get some feedback before I go nuts. My heads are 440 source, the intake is an Eddy RPM with mopar stamped on it, both are hand ported and flowed by me. The ports average (on just the head) 301 CFM at cam lift of .560. I only flowed the #1, #2, and #7 ports on the intake. On Dual planes #1 and #7 tend to be the lowest flowing because of the hard roof transition into the plenum and the tight radius into the port; and are followed by the #4 and #6 which have a 90 degree roof transition into the deeper plenum. Flow numbers for #1 and the #7 were 296, and 303 respectively, with the #2 coming in at 329. I cut down and reshaped the plenum wall from a square from to a half moon, I was very conservative when I re-radiused the plenum and carb pad transitions at the time, but now I have a Dakota instruments ultrasonic gauge with 9" probes for aluminum and cast porting. I also have a mig and tig that can weld aluminum so....

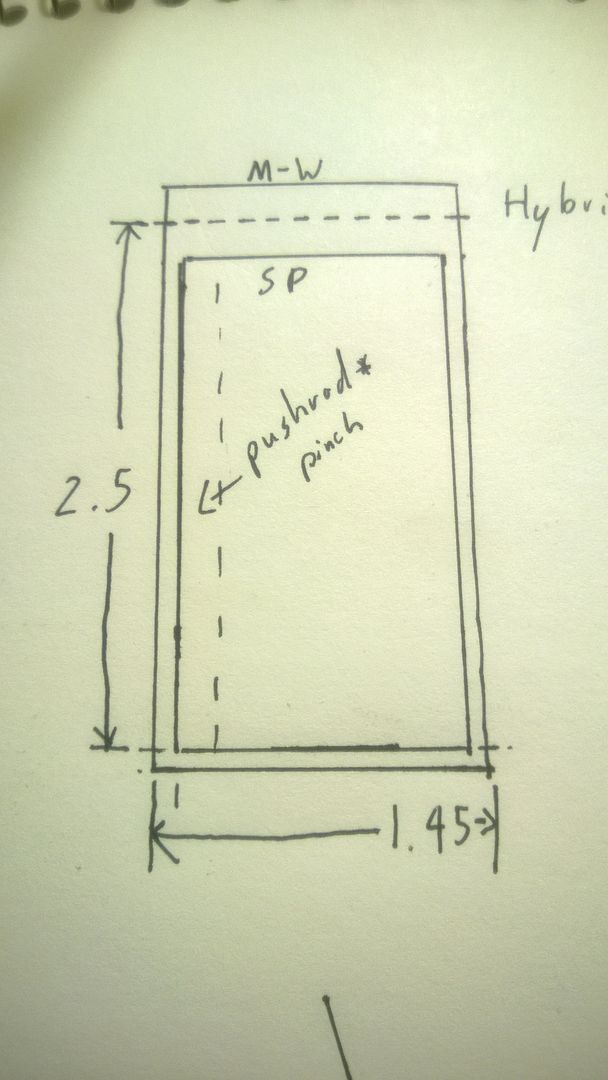

Standard Port: Good for a street motor, but the pushrod pinch further diminishes port cross sectional area, and probably reduces high lift flow.

Size is around 1.26 x 2.26 on average (numbers range depending on source, lol, so don't quote me)

Max-Wedge: Large Cross Section, high lift flow is great, but velocity at low engine speeds takes a beating, unless your running a stroker.

Size is around 1.38 x 2.63 on average (" ")

Hybrid: Standard port has a higher port floor than Max Wedge - advantage Standard port, Max Wedge has a Higher port roof than Standard port - advantage Max Wedge, Max Wedge port is wider, but requires offset pushrod; however, to open the standard port up to the gasket line you will need an offset rocker anyway - so I give a slight nod to the Max Wedge.

So, I was thinking of a port with the roof height and width of a Max Wedge, and the floor depth of the Standard port. I will make some drawings and Post my Ideas shortly.

The Goal is a head and intake with good drivability and overall flow numbers that land more in race motor territory, and to try this with my current top-end architecture.