Ok here we go

my tips trick etc on rebuilding a steering box

first and foremost, patience

I had to redo a few things because I rushed a few things on reassembly. I tend to get a little excited when I am putting things back together

so I always need to remind myself to slow down and read the dame FSM or other instructions while I am working.

Next

take pics while you are dissembling everything

I found a few spots where the pics were very helpful. There is a washer under the snap ring on the pitman arm end of the cross shaft that is not shown in the exploded view in the FSM. I went back and noticed this in my pics and was able to put the washer in.

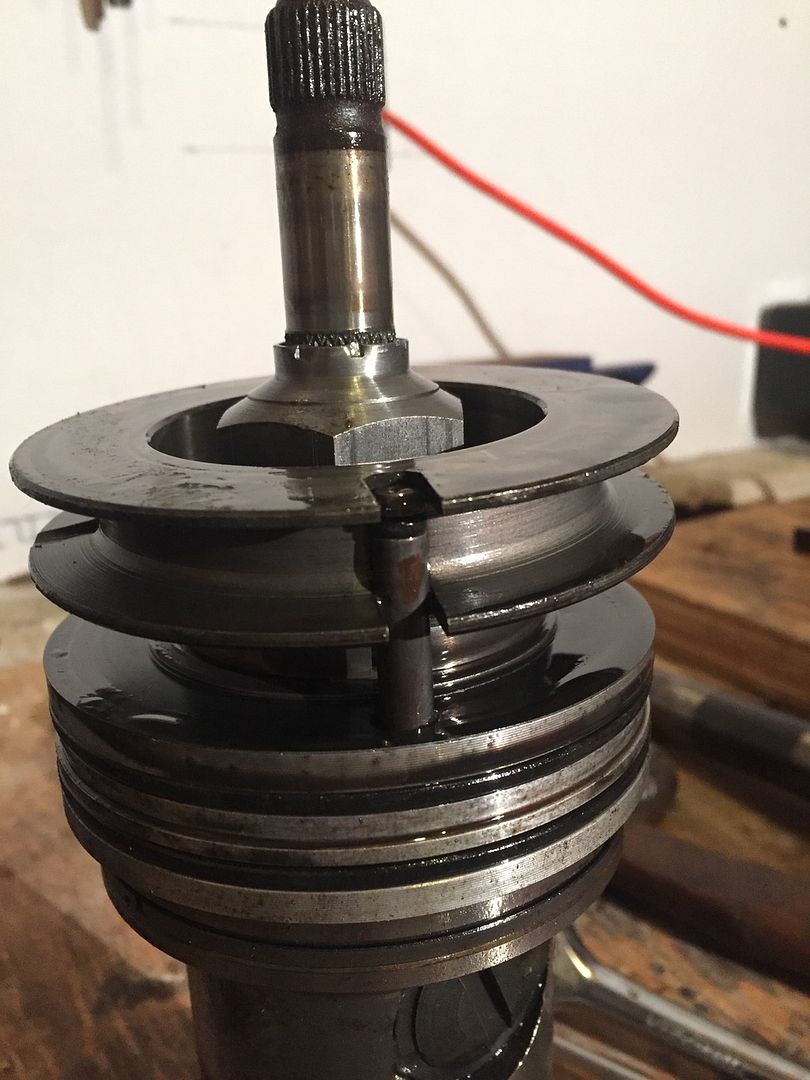

When you are assembling the power unit, the race (the this piece with the slot in it pictured below) has a hole in one side.

The spacer below that fist over the race, also has a hole in it:

Oh you guessed it

those two holes need to be aligned. Seems simple right, but I missed this while I was test assembling my spare box

and it is a pain to get the power unit back out once it is installed.

On that topic, the holes in the spacer are important and need to be aligned with the hole in the top of the box

when you install the power unit, the teeth also need be aligned in the cross shaft bore.

I had the hole in spacer off more than I would like to admit. Like I said it is a pain to get the unit back out. It is possible to move the spacer by tapping the head of the power unit to align the holes, but it is a pain. I figure this was the lesser of the two evils.

Installing the power unit is somewhat of a pain because it is a tight fit and all the weight is at bottom. I found I had to give the cover a few whacks with the handle of my hammer to get it down into place, but it will go.

As I said above, make sure you take lots of pics and read the step by step instructions in the FSM, there are few steps that are important and a bit of a pain to go back and re do.

When you first pull it apart it is a little intimidating, but once you see how it all comes apart it starts to make sense and goes back together fairly easy.

All in all I have it back together and everything spins nice and freely, So I am very hopeful it will work well.

I still need to figure out a way to torque the two spanner nuts...but I am sure I will figure that out.

If anyone has any questions on doing this themselves I am happy to offer whatever help I can.

Jason