Well I got off my butt and started them. They go off tomorrow to get seats installed, new 11/32 valves, springs, retainers, etc.... and ported!

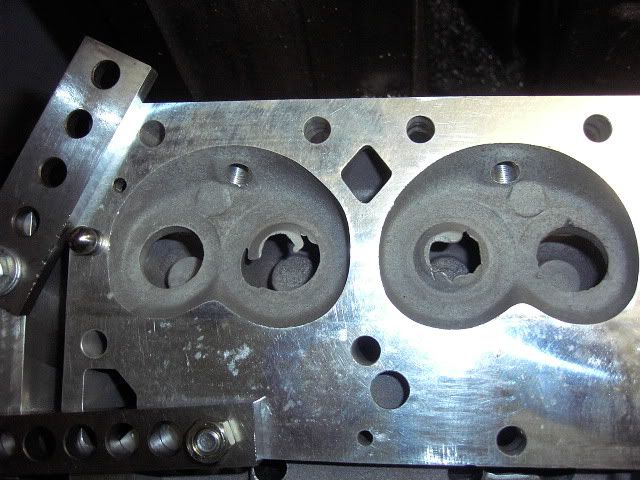

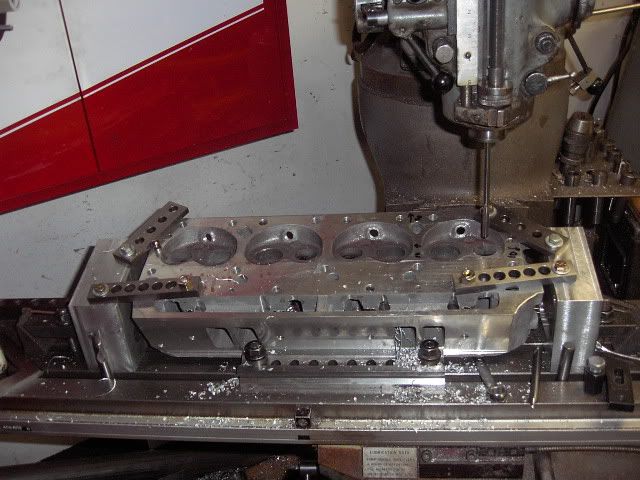

I machined the valve seat area to the ID size of the valve seats so we would have some idea now how much has to come out of there. There is lots of material to remove!

I moved the valves away from the rocker shafts by .035" and spread the valves apart by .020" from the stock locations. I took me quite a bit of time to make the fixture for holding the heads square. Valve angle is as stock 15 degrees.

Sure is fun to have some equipment in the garage! Comes in handy!

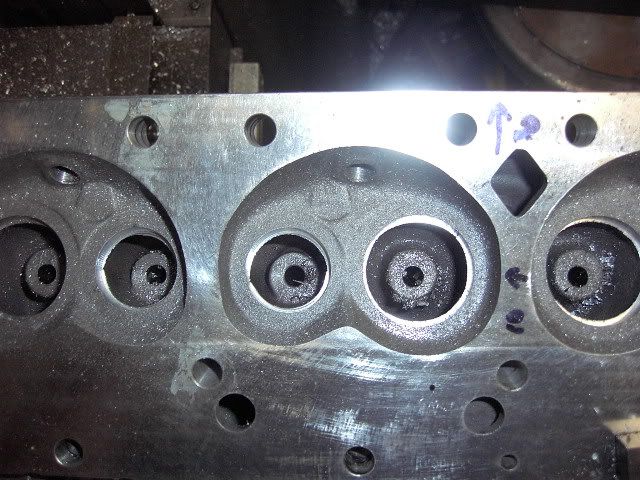

Here is how they started.

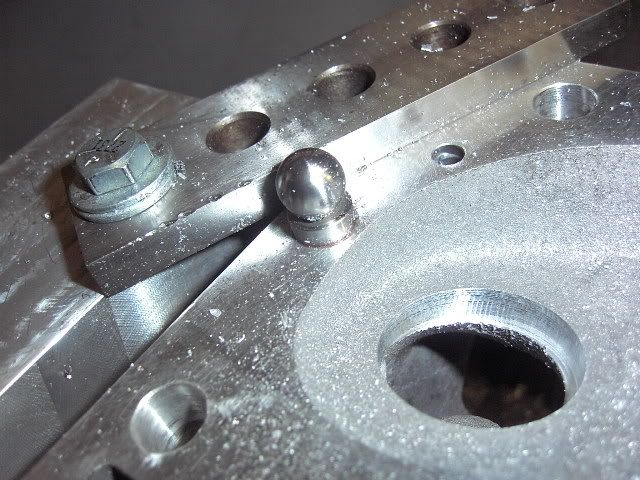

Tooling ball was used to find valve locations of a stock head

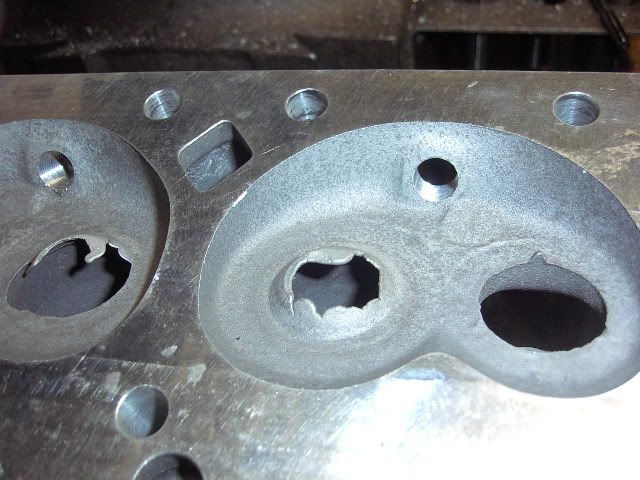

Here is the finished head, or as far as I'm machining it too.