Okay, here's some more updates.

First came the initial clearance on the drivers side, which I don't have a photo of. It was relatively minor, and the factory oil pump fit....

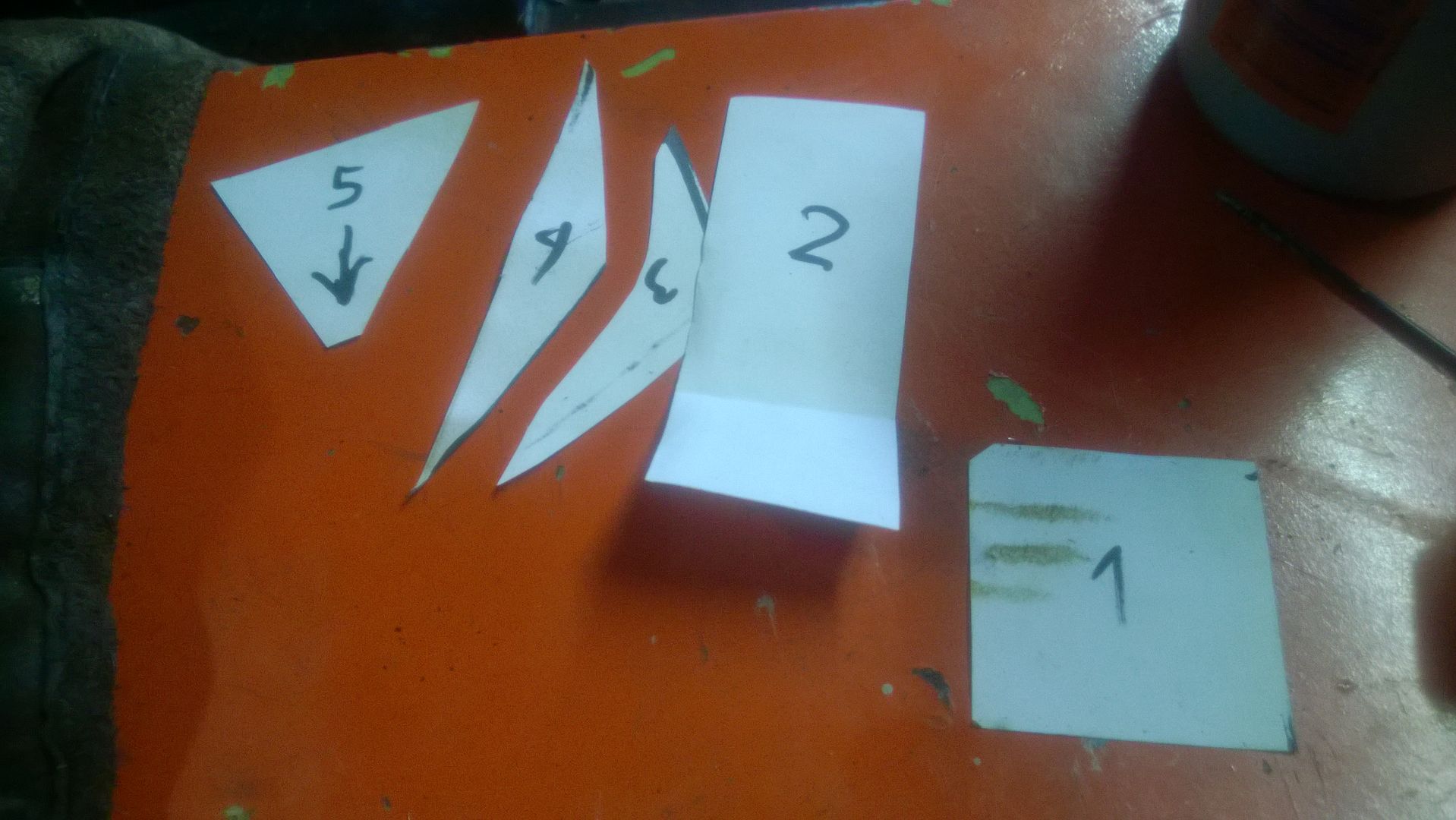

However, there are enough differences between the melling Hi-Vol and the factory pump to cause more clearance problems. Now remember that I dropped the motor an inch and set it back 1.25 inches. The real issues stem from differences in the cap of the melling pump on its back side. So first came the initial round of chopping.

Then came the first round of gussets to lock everything together before the really drastic clearancing began. Started by finding areas that could be tied together without causing clearance issues first.

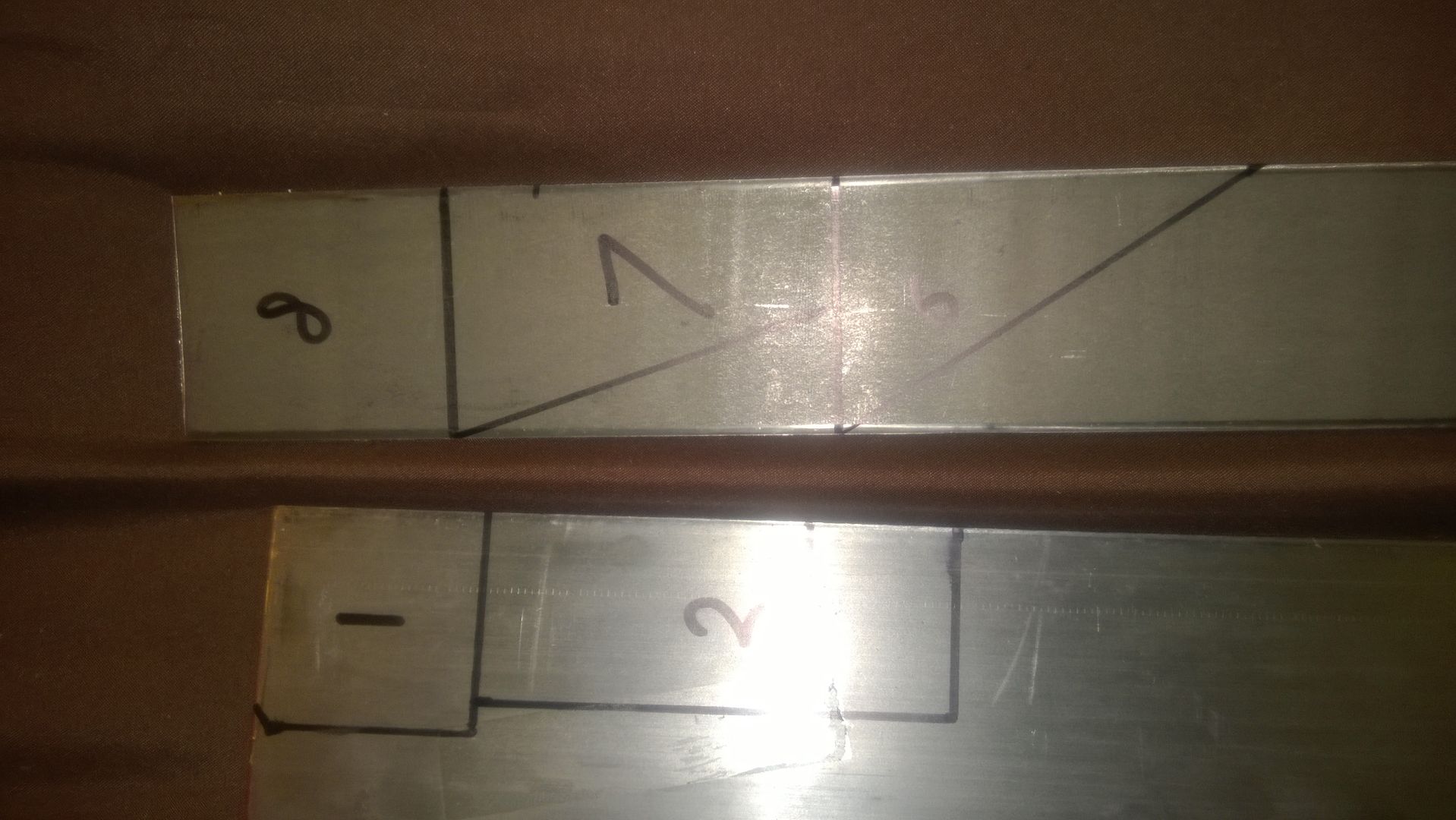

Here I tied the bottom side of the brackets together, I also re-welded all the factory welds while I was at it, they were so terrible its a miracle that anything held together. Seriously, way to much heat, tons of porosity, it looked like they were using a torch for gods sake.

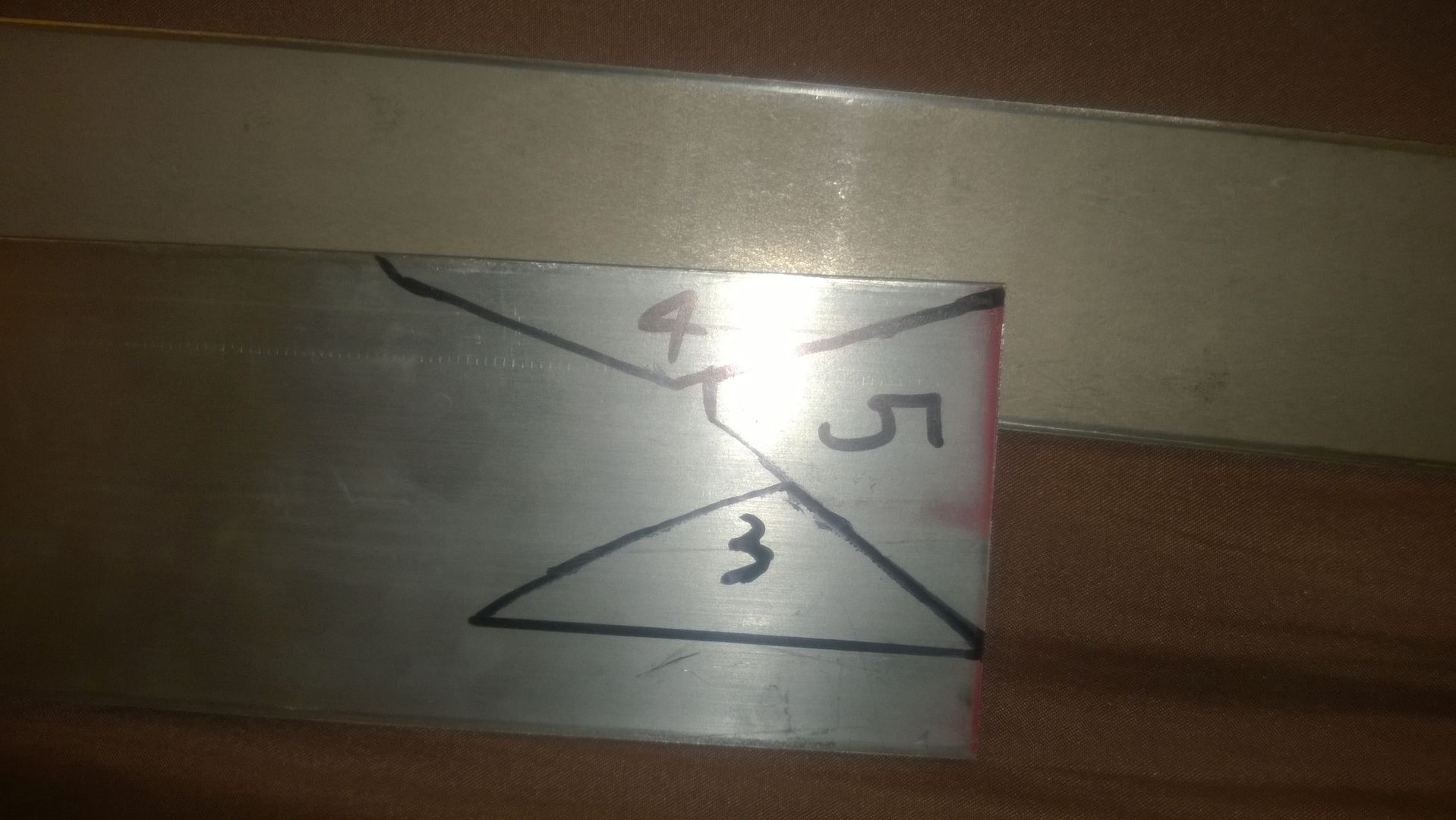

The next step was to fully seem weld the K member, clearance it some more, and then add the last 3 gussets.

The passenger side mount however has no real issues, but I wanted it to be more sturdy.

Here is a full view of the K member.