Ok, so here's part II of what I did to upgrade my steering shaft. The stock coupler leaves a lot to be desired. More than likely yours is worn out. They sell rebuild kits, but after all of that the spring clip is hard to get on, and when it comes off it makes a mess. And then it wears out again.

So, lots of folks are going to steering u joints. Less play, and they can provide more header clearance. But then the question of binding comes up, because the stock coupler also slides in and out. I don't actually think this is a huge deal, but I figured I'd humour the doomsdayers and see if there was something I could do about it.

What I came up with was a telescopic DD shaft from Borgeson that I bought

http://www.ebay.com/itm/Borgeson-Steering-Shaft-Telescopic-Steel-9-5-13-range-3-4D-shaft-1-DD-Tube-/181085054860?pt=Motors_Car_Truck_Parts_Accessories&hash=item2a2982a78c&vxp=mtr". This is a short one, 13" fully extended, 9.5" fully collapsed. And, it goes from 1"DD to 3/4" DD.

The 3/4DD side allows the use of most steering couplers, including this beauty from Borgeson, #034934. This ones a 3/4DD to 3/4" 36 spline vibration damping u joint, and it fit my Flaming River steering box great. **Disclaimer** not all mopar steering boxes use this size!!!

I got mine from summit,

http://www.summitracing.com/parts/brg-034934/overview/. $110. Not cheap, but since nothing else will dampen the vibrations anymore, I went with this one. One disadvantage to this one is its almost exactly the same diameter as the original, so, not much header clearance savings.

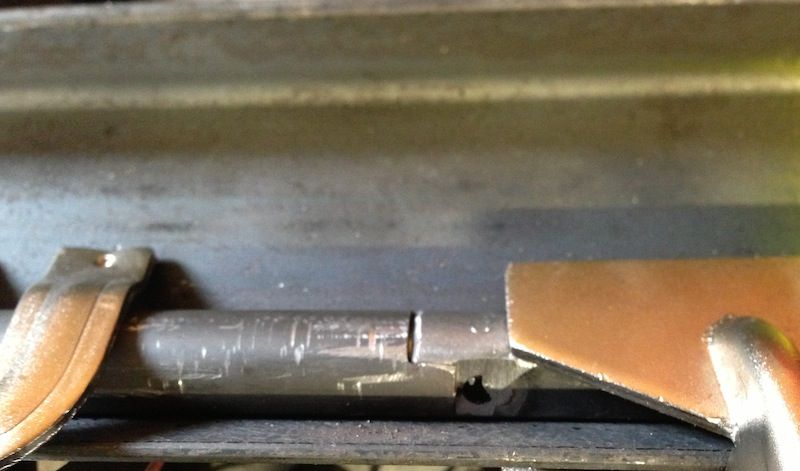

Next is the hard part. I cut the power steering shaft that I had and ground and filed a notch in it to accept the 1" DD telescopic shaft end. I did this so that it wasn't butt welded together, and because it made it easier to keep the shaft aligned properly. After all, I fit this with a ER16 bearing at the lower column, so no play to make mistakes. You can see that the steering shaft is 1" at this point, so you're left with a couple of little "tabs" that slide over the flat sections of the 1" DD shaft. After all, the outer diameter of that is 1" on the rounds.

I then clamped the steering shaft and telescopic shaft together in a piece of channel I had to keep everything straight, and welded it together.

Unfortunately, this is where I messed up my "how to". I stopped taking pictures and I forgot to write down the length of the stupid steering shaft where I cut it to set it up for my Flaming River steering box. This is on my '74 Duster though, so the length wouldn't help here much for an E-body. Anyway, I set it up so that the telescopic section of the steering shaft was collapsed about 1", so, it will still extend up to 1", and collapse up to 2.5". The additional extension I left mostly in case I change to a regular steering u-joint at some point, or if they change the length of the vibration damping unit. You'd want to leave a little extension for body flex, but a 1/4" would be more than enough for that. After all, the point was to prevent the u-joint from binding if there's chassis flex.

Keep in mind that cutting and splicing the telescopic section DOES keep the original collapsing shaft from collapsing as far as it normall would in an accident. BUT, I know the original part of the shaft will still collapse close to 6", and the telescoping section will collapse another 2.5", so that should be plenty. If its not, you're in trouble anyway. Again, that was for my Duster, I think on an E-body the steering shaft is longer anyway, so you'll keep even more of that collapse distance.

Next I fit the lower column bearing (see this thread

here), drilled the 3/4DD end of the shaft for the set screws, and reassembled the whole mess.

And then put it in the car!

Yes, the coupler looks HUGE. Most of it is the angle of the photo. I measured it, I swear its a little less than the diameter of the original coupler. Also, you could skip the vibration damping piece and just put on a regular U joint if clearance is what you're looking for here.