On to the next project...the air cleaner.

I wanted something custom but didn't exactly know what I wanted. I did a lot of looking at pictures on Google to get ideas. Before I worried about the design though, I needed to see how much clearance I had to work with. With the radiator removed and the hood closed, I was able to take some measurements. It was going to be tight. The Edelbrock carb really limits the amount of drop you can have on your air cleaner base. The electric choke sticks out the side and limits you to a 3/4" drop. With a 3/4" drop, a 3" tall filter was going to be VERY close to one of the hood braces. I could easily use a shorter filter but I really don't like how they look. 3" is about the minimum height that really looks good IMO. So, I found a 14" diameter open element air cleaner from Summit that was only $20. It had a 1" drop base and came with a 3" filter. It was cheap enough so I bought it.

When it arrived I verified what I had read online. The 1" drop hit the electric choke. It was fairly close to clearing so I thought I could modify it slightly to fit. Since I can't weld, I took the base to a friends house. We cut a flap out of the base, bent the metal inward a little bit and welded everything back together. Now, the 1" drop base clears the electric choke cover. That 1/4" does make a big difference on this A-body. I did have to slightly modify the air filter. The notch didn't allow the filter to sit down flush on the base. I had to grind away some of the rubber on the inside of the filter so it would lay flat. Here is what we did to get the base to fit...

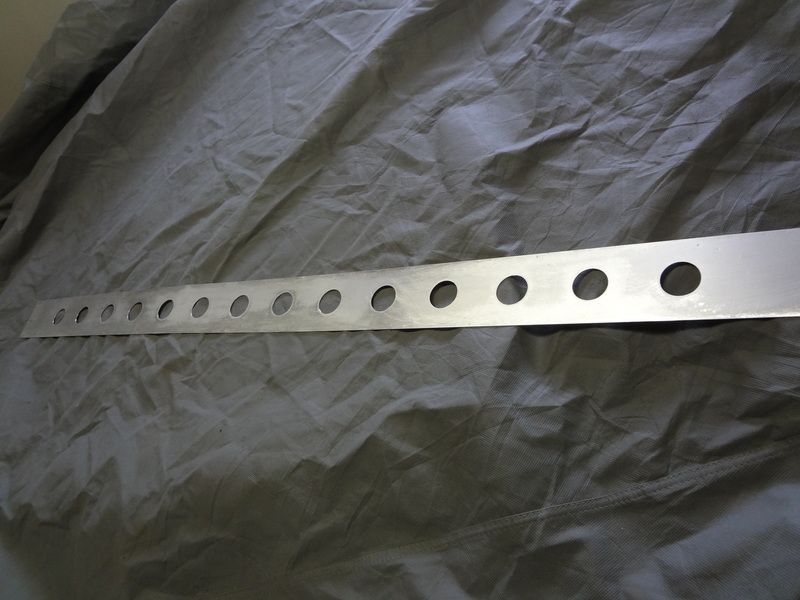

Now that I knew it would fit under the hood, I turned my attention to making it look better. I found a design online that I thought I might be able to handle since my fabrication skills are very limited. I went down the road from where I work and bought a piece of .025 aluminum that was 3" high and 4' long. I tried a couple different hole layouts on paper to get the one that I liked the best. I ended up drilling (14) 1 1/4 holes along the aluminum sheet.

I had previously purchased a 1 1/4" dimple die when I was making my trans cooler bracket. I used that to dimple all 14 holes.

Once that was done, all that needed to be done was wrap the aluminum around the air cleaner. I wasn't sure how the aluminum would bend with all those dimpled holes in it. It actually bent very easily.

With the aluminum cut to the correct length, I riveted the ends together. The rivets will be on the back side so they won't be seen. There is a little gap between the air filter and the outside lips of the lid/base. This aluminum insert fits in that gap.

I actually don't have the hood clearance to use a standard wing nut. I've got a custom fastener in mind to attach the air cleaner but I haven't built it yet. Here you can see how it looks on the engine. I also bought some aluminum plug wire separators off of Ebay. I started playing around with plug wire routing with a set of old wires I had sitting around. I think they'll work out nicely.