This morning I dyno'd my 440 at Morgatini's shop in West Wyoming PA. First off would like to thank my machinist, Dan Morden, for doing an excellent job machining and doing final assembly, as well as Bob M. for running the dyno.

Recipe:

78' 440 block from a thrashed Cordoba: bored .040 over SRP 4032 forged flat tops, Eagle H-beam rods, 69 factory forged crank 3.75 stoke ground 20 under on M&R, zero decked, line bored and honed, 440 Source billet main caps, ARP studs, Clevite bearings, Sealed Power 1/16-1/16-3/16 plama moly file fit rings.

440 source heads: bowl blend, gasket match, full port clean-up, polished and cc'd chambers (done by myself), shaved .010, the chambers relief cut by the intake valves, and a quality check on valve guides/installed height.

440 source 1.6 ratio roller rockers, Rhodes V-Max lifters, Comp XE-21-227-4-HL camshaft, Comp pushrods.

Mopar Performance High Rise Dual Plane (eddy rpm): re-radiused entries from plenum to number 1 & 7 cylinders and port-matched to heads (done by myself), BG 850cfm annular discharge vacuum secondary carb, Accel 71000 series billet distributor, 1 3/4 inch primary tube 3 in collector headers supplied by Bob for the dyno (1 7/8 hookers wouldn't work).

The motor pulled strong and wasn't very sensitive to timing adjustments on the dyno. Going from 36 to 40 degrees only dropped the HP by +/- .5 and Torque only swayed +/- 2-3 ft. lbs.

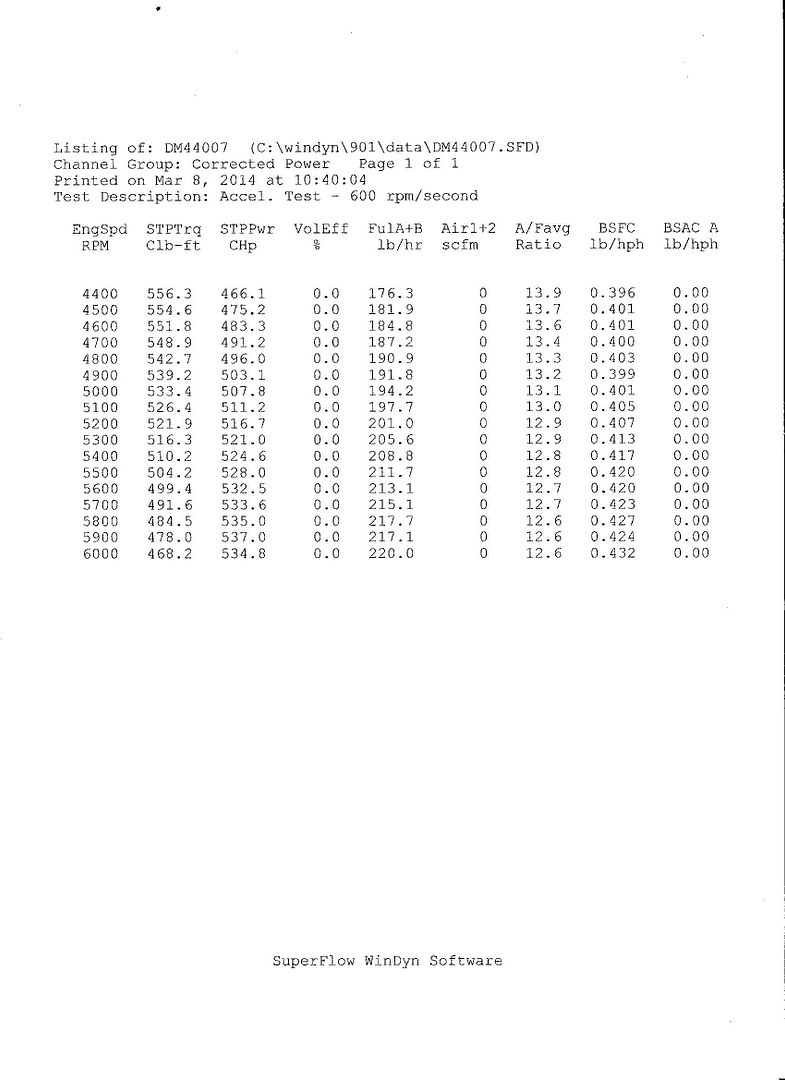

Here's the sheet from the dyno.

I have video as well will post it shortly.